The defining feature of wa-goya-gumi (和小屋組, lit. ‘Japanese roof framing’) construction, in contrast to the other forms of roof framing (koya-gumi 小屋組) we have considered to this point, are the rows of roof posts (koya-tsuka 小屋束) erected on top of the transverse roof beams (koya-bari 小屋梁). These roof posts transfer the dead load of the roof indirectly to the ground floor posts (hashira 柱) via the beams. In most wa-goya roof framing, the rows of roof posts support underpurlins (moya 母屋) which support the common rafters (taruki 棰 or 垂木); wa-goya roofs do not typically have principal rafters (sasu 叉首), but as we shall see there are examples which do.

Wa-goya roof framing is still commonly used in new-build houses in Japan today, in a somewhat rationalised form, with metal hardware and diagonal bracing to improve performance under lateral load from wind and earthquake, and squared, straight roof beams.

Modern wa-goya-gumi (和小屋組) roof framing, showing posts (hashira 柱), wall beams (noki-geta 軒桁), transverse roof beams (koya-bari 小屋梁), corner bracing (hi-uchi-bari 火打梁), roof posts( koya-tsuka 小屋束), penetrating ties (koya-nuki 小屋貫), diagonal bracing (koya-sujikai 小屋筋交), underpurlins (moya 母屋), ridge beam (munagi 棟木), and rafters (taruki 垂木). Only one half of the roof is shown for clarity.

In most traditional minka, the roof beams are irregular, curved pine logs (matsu-maruta 松丸太); in order to minimise deflection, these beams are oriented so that their ‘backs’ face upwards, forming a natural arch, meaning that the roof posts in any particular longitudinal row of posts are not of uniform length. The posts are connected and restrained from leaning out of plumb in both longitudinal and transverse directions by penetrating roof ties (koya-nuki 小屋貫); the upper and lower faces of these ties are typically in contact with one another within the roof posts (i.e. their mortises are connected); however in older minka the transverse and longitudinal ties may be widely vertically separated.

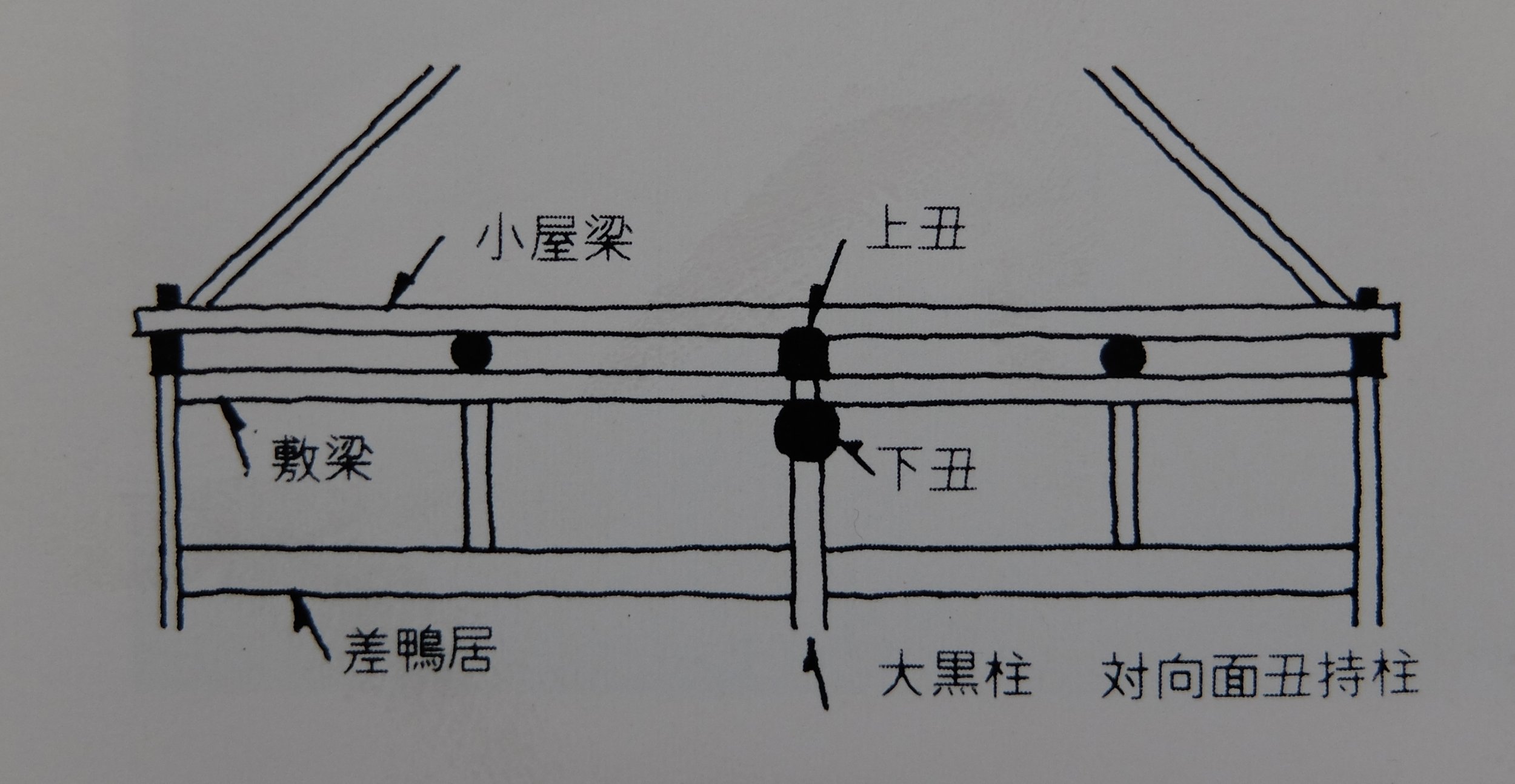

If the width of the building is large and cannot be spanned by a single transverse beam, it is divided into two or three spans by intermediate posts, usually located in the plane of the floor plan partitions where they won’t be in the way of the inhabitants. Longitudinal (parallel to the ridge) beams, called shiki-bari (敷梁) or nakabiki-bari (中引梁), support two transverse beams called nage-kake-bari (投掛梁) that run out to the external walls on either side. The longitudinal beams might be supported directly on the internal posts, or in the middle of a short, elevated transverse beam called a tenbin-bari (天秤梁).

Wide-span buildings can give rise to another problem: the roof posts may be too long to be effectively stabilised, even with penetrating ties. In this case, one solution is to add one or two tiers of roof beams above the main roof beams, arranging them so that roof loads are distributed as evenly as possible.

The following five section diagrams illustrate how wa-goya framing developed to accommodate greater spans by the use of tiered beams, longitudinal beams, and internal ground floor posts:

1. A simple short-span wa-goya roof with only three rows of roof posts (koya-tsuka 小屋束) on the transverse beams (koya-bari 小屋梁), and underpurlins and a ridgepole set on the roof posts to carry the common rafters (taruki 棰).

2. A wider building, but still spannable by a single koya-bari, and five rows of koya-tsuka; the central three rows of longer koya-tsuka are stabilised by penetrating ties (koya-nuki 小屋貫) in both directions.

3. The wide span is divided into two with a row of internal ground floor posts (hashira 柱), upon which is set a longitudinal beam (naka-biki-bari 中引梁); the naka-biki-bari supports two transverse beams called nage-kake-bari (投掛梁). There are eight rows of koya-tsuka, an upper transverse beam (ni-ju-bari 二重梁), and above that shorter connecting beams (tsunagi-bari つなぎ梁) which stabilise the structure in place of penetrating ties (nuki 貫).

4. The building is divided into three spans, with two rows of internal ground floor posts. The two outer transverse beams (tsunagi-bari 繋梁) act to tie the posts together but do not bear any of the roof load. The central, elevated ‘balance beam’ (tenbin-bari 天秤梁) carries a massive central longitudinal beam, which in turn supports two transverse ‘rising beams’ (nobori-bari 登り梁); it is these nobori-bari which bear the roof load via nine rows of koya-tsuka.

5. Again there are three spans, but this building employs a very long transverse beam that runs the full width of the building and forms three continuous spans over the two internal ground floor posts; on this beam is carried a longitudinal beam (naka-biki-bari 中引梁), which in turn carries two nage-kake-bari (投掛梁) transverse beams. There are two additional tiers of transverse beams above this: the ni-ju-bari (二重梁) and san-ju-bari (三重梁). There are eleven rows of koya-tsuka, although note that some terminate at the san-ju-bari and some at the ni-ju-bari, without directly transferring their roof loads down to the nage-kake-bari.

Wa-goya roof framing is typically associated with tiled roofs, but thatched examples can also be found in areas with heavy snowfall and on particularly large roofs.

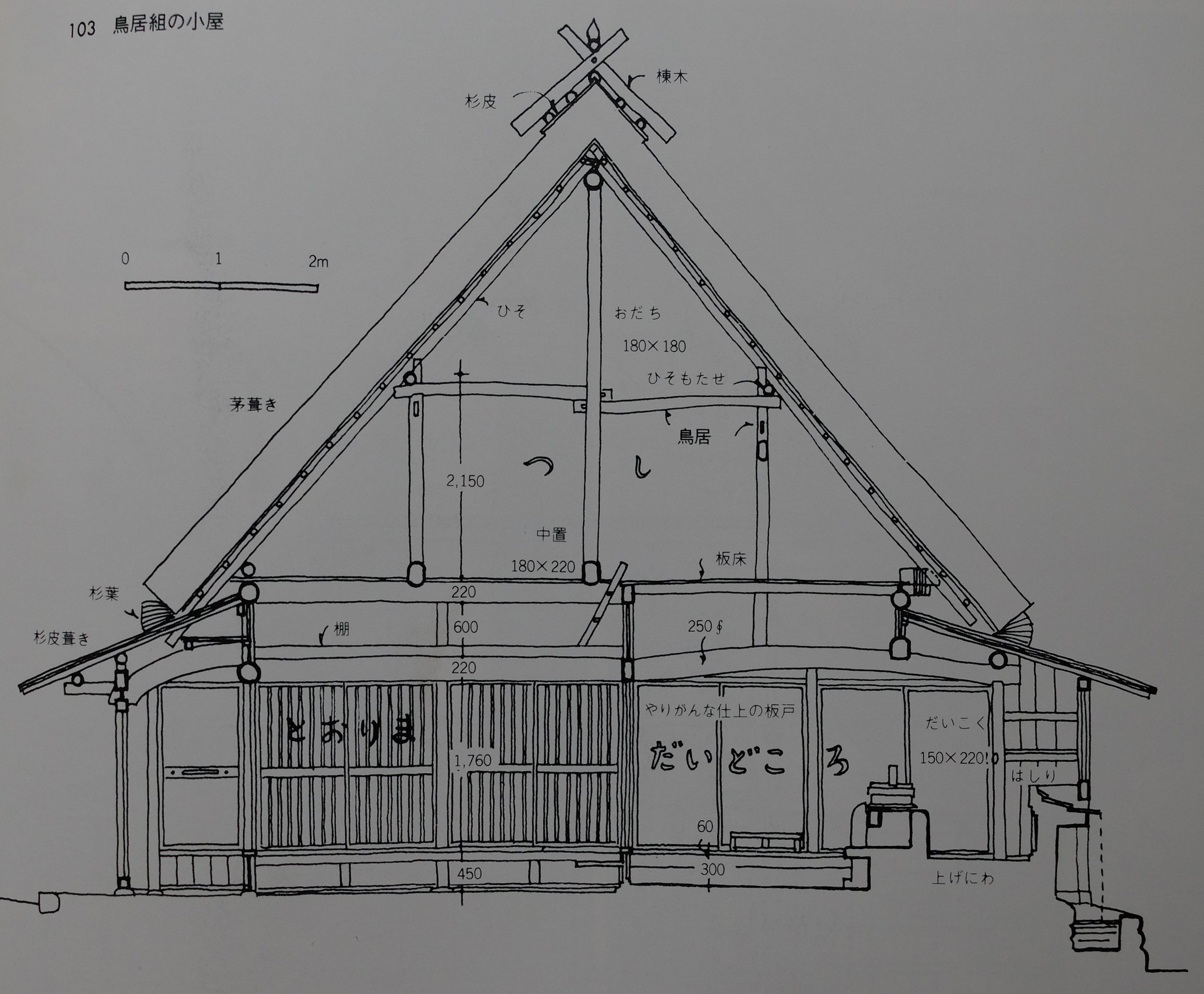

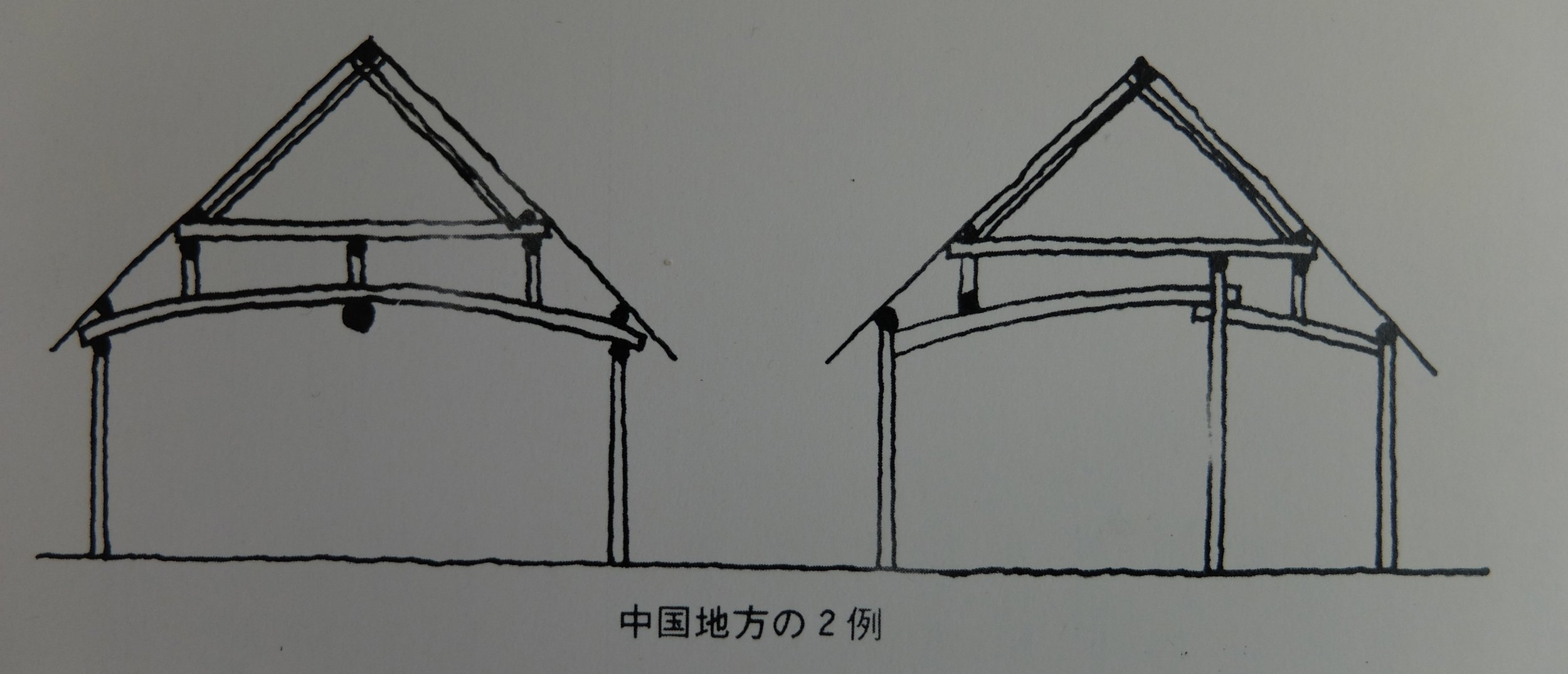

If the sasu-gumi (叉首組) framing method covered in the last few posts is employed in large-span minka, there arises the need to support the long principal rafters (sasu 叉首) at intermediate points to prevent them sagging. This need led to the development of sasu-gumi into the more complex torii-gumi (鳥居組) method, also discussed previously, in which two roof posts flanking the central odachi post support underpurlins (moya 母屋) that in turn support the sasu. This system might be regarded either as a precursor form of wa-goya construction, or perhaps a hybrid of the two systems. Such combination roofs are commonly found from the Chūbu (中部) region northwards, in the Tо̄hoku (東北) region, and elsewhere.

A wa-goya roof that incorporates principal rafters (sasu) in Akita Prefecture in northern Japan, an area of high snowfall.

The Sasaki house in Nagano Prefecture, a region of high snowfall. The roof framing incorporates wa-goya-gumi elements (roof posts, upper roof beams, penetrating ties) into a sasu-gumi roof structure.

Section diagram of the Sasaki house. The curves in the long continuous transverse roof beam (koya-bari 小屋梁) are cleverly oriented to ‘snake’ around the two outer longitudinal beams (uke-bari 受梁), which support it, and the central longitudinal beam (ji-mune 地棟), which it supports. Three rows of roof posts (koya-tsuka 小屋束) bear on these beams and are connected with penetrating ties (koya-nuki 小屋貫) in both directions. The uppermost central roof post is termed the shin-tsuka (真束). Interestingly, the roof run is divided into two rows of half-length sasu: the upper (sasu 叉首) and lower (kiri-sasu 切り叉首, lit. ‘cut sasu’).

A similar structure to the Sasaki house, but without an upper central crown post (shin-tsuka) The principal rafters (sasu 叉首) and upper transverse beams (tsunagi-bari 繋梁) form an A-frame structure in the upper half of the roof space; in the lower half, three rows of roof posts (koya-tsuka 小屋束) transfer loads to the roof beams below.

A roof in Tochigi Prefecture showing central roof post (shin-tsuka 真束) and two flanking roof posts (waki-tsuka 脇束) to support the principal rafters (sasu 叉首).

A partly disassembled minka in Kanagawa Prefecture with roof framing that utilises both crown posts (odachi おだち) and principal rafters (sasu 叉首). Note that the sasu are not full-length from ridge to eaves; rather the run is divided into upper sasu (simply called sasu) and shorter, more slender lower sasu (kiri-sasu 切り叉首).

The magnificent thatched wa-goya roof of the Egawa House in Shizuoka Prefecture. A forest of roof posts, thicker and longer than the ground floor posts in the average minka, are connected with equally numerous penetrating ties, the whole forming a dense three-dimensional lattice.